ELECTRONIC

SURPLUS

CATALOGS

The Big List

INEXPENSIVE FET ELECTROMETER ARRAY

1994 William Beaty, Museum of

Science, Boston

The schematic depicts the basic 'cell' of the Inexpensive Visual

Electrometer Array. The MPF102 is a Field Effect Transistor available

from Radio Shack and many other places. Any LED will do, but diffuse

wide-angle, high-brightness types like MV5753 (Active Electronics) are

best. Screws with nylon insulators were used in the panel. With a

1-in. wire antenna,

the circuit is small enough to be built atop a 9-volt battery clip, then

used as a handheld probe. With a 24-in. wire antenna, the circuit is

sensitive enough to respond to the waving of a charged comb or balloon

/across the room.

In the present circuit, the LED turns on when a positive charge approaches

the antenna, and turns off when negative charge approaches. The 1-meg

resistor limits spark current should any large, charged persons actually

touch the gate wire.

The earth-ground point in the circuit can actually be at any of the

schematic nodes, not just the one shown. And if the circuit is

battery-powered, you can even ground the gate and use the entire circuit

and battery as the "antenna." I use the point shown in the schematic

because it allows the handheld version to easily be lit/darkened via the

battery: Hold the gate lead, touch one battery terminal, then release the

gate lead. Depending on the + or - terminal you touch, the LED goes on or

off.

While extremely inexpensive, this particular circuit has a problem.

It can be turned on and off! In other words, it suffers from inductive

charging via the diode junction which is part of the FET gate, and this

makes the circuit behave differently with positive signals than with

negative. If a negative charge approaches, the LED turns off, and when

the charge is removed, the LED turns on. The opposite is NOT true for

positive charges. If a positive charge approaches and the LED is on, the

LED will stay on, but the FET's internal diode will turn on and allow the

gate wire to become charged. When the positive charge is removed, the LED

will turn off and stay off! There is a "memory" effect involved with the

circuit, and so the circuit does not always reflect the state of the

e-fields in the space around it. However, it is amazing that such a simple

device detects e-fields at all, and the price is so low that every student

can have their own e-field sensor. For hard numerical data, an expensive

electrometer instrument can be used instead. If you are building a much

smaller array, you might want to consider using a FET input opamp circuit

and red/green polarity indicator LEDs.

THE ARRAY ELECTROMETER

To protect the circuit from direct discharges, I placed a 10meg resistor

in series with the lead wire coming from each antenna screw, and I

connected an NE-2 neon pilot light between the FET gate and earth ground.

The glass of the neon bulbs turned out to cause humidity problems

(decreased sensitivity) on moist days, so I painted the base of each bulb

near the lead wires with red-brown, high-voltage insulating spray paint.

It's important to not touch the base of the neon lamps either before or

after painting, since fingerprints become conductive when moist. Handle

them only by the lead wires. If there are finger prints on them, scrub

them off in a bowl of rubbing alcohol.

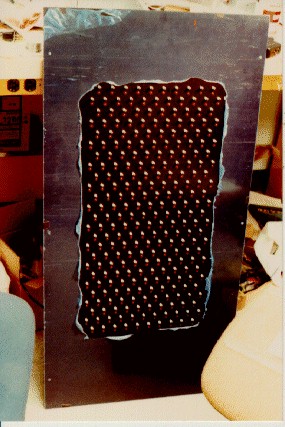

For the main panel I used sheet aluminum anodized with black color (which

I picked because the black wasn't insulating,) bought from a decorative

metal supplier. It was covered by a peel-off protective sheet which is

seen in the JPEG image (and must be removed when complete.) If you use

another material for the plate, be aware that if the panel is coated with

a good

insulator such as paint, it also becomes a good trap for ionized air, for

"frictional" charges, etc. It invariably will become charged up and

distort the light patterns terribly.

You might wish to experiment

with

placing the whole panel behind glass. This will protect it from direct

discharges, but if the glass becomes charged (will there be fur or cloth

provided?), the exhibit will go flakey on you. The conductive panel is

connected to earth ground.

Each "antenna" screw was next to an LED. The screws were 6-32, and

stuck out about 3/8" from the panel. I think I used 3/4" screws, to give

adequate length out the back. I used black "socket cap" screws just to

keep everything black for good contrast. The vertical rows of sensors

were about 1" apart, the screws were about 1.7" spaced vertically, with

each LED about 3/4" from each screw. I bought white nylon insulators from

an electronics catalog (digikey.com.) One of the insulators was of the

screw-insulator

type, it was like a 6-32 shoulder washer, but with a little thin tube

sticking out

of the side. The other insulator was an 8-32 unthreaded nylon spacer 3/8"

long. The two insulators meshed together with a slip-fit action, which

totally isolates the screw from touching the grounded metal panel. Drill

each hole with a #16 bit. The

6-32 washer is mounted from the rear of the panel, the 8-32 washer is

placed over it

from the front,

the screw is inserted from the front, then the nut and solder-lug are

screwed on

the back.

Keep the nylon parts very clean. Don't open their bags

until

you're ready and install them while wearing gloves. If the washers get

any salty fingerprint contamination on them, they can become conductive on

humid days. If one or more segments stop working on humid days, it means

that surface contamination is somewhere present on the washers, on the

NE-2 bulb, or even on the FET itself.

To power the array I first soldered each FET to its adjacent LED, to the

antenna lug, and to the NE-2 bulb. This leaves each element with two

disconnected leads, a positive and a negative. I used horizontal wires to

connect each row of elements together in parallel (I stripped small holes

in the insulation to allow solder connection.) These wires are visible in

the photo above: yellow for positive, bare wire for negative. Then I

attached long thin pieces of copper circuit board vertically to the

aluminum panel, then soldered all the horizontal wires to the circuit

board strips.

Here's an advanced feature for the ambitious designer. I figured out how to reset the whole array so the LEDs would all dimly glow. I connected each antenna-screw to a 15pF 200V capacitor, all going to a common bus. I found that if I raised this bus voltage to 150VDC, then lowered it to zero, then any pattern on the array would be wiped out. Note that it might be possible to damage the FETs if you SUDDENLY connect this array to -150VDC and then to ground. So, I used relay switching of resistors and capacitors to slowly charge the array to -150V in about 0.1 second, then discharge it again in about 0.1 second. Such a slow change will keep the gate currents low and prevent transistor burnout. A pushbutton and a timer circuit runs the relay sequence.